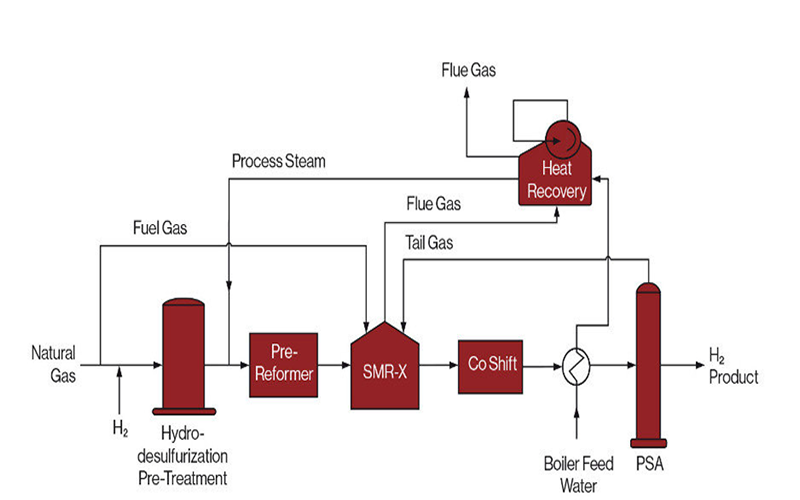

SMR-X™ is a new generation technology from Air Liquide Engineering & Construction that produces hydrogen without co-producing excess steam. Compared with conventional steam methane reforming, SMR-X™ features higher thermal efficiency at low steam co-production ratios and emits lower levels of CO2.

Lower production cost through internal process heat recovery

With SMR-X™, the desulfurized feed gas is mixed with process steam, passes through catalyst-filled reformer tubes and is then cooled by heat exchange with process gas inside the tubes. The unit’s internal heat exchange coils have been designed for maximum reliability and optimized efficiency so that SMR-X™ operates at zero steam export with low overall feed and fuel consumption.

While the bulk of heat to SMR-X™ is provided via radiative heat transfer, around 20% of the process heat is supplied by internal heat exchange. This results in reduced furnace size and fewer reformer tubes compared to traditional steam reformers. Additionally the internal steam system design is simplified, since no steam is exported.

Advantages

- Compact reformer design resulting in lower capital expenditure (CAPEX)

- Overall feed and fuel consumption as well as CO2 emissions reduced by 5% compared with conventional Steam Methane Reformer

- Zero export steam

- Simplified steam system

- Design for maximum reliability and availability in operation

Key figures

- Capacity: up to 100 000 normal cubic meters per hour (Nm³/h) Hydrogen

- Feed+fuel: 13.8 mega joules per normal cubic meter (MJ/Nm³) Hydrogen