Five decades after the construction of Nigeria’s five crude oil terminals by foreign multinational companies, the nation’s oil and gas industry is set to witness an epic commissioning of its sixth crude oil terminal – Otakikpo crude terminal, built by an indigenous exploration and production company, Green Energy International Limited (GEIL).

Sequel to the completion of the Otakikpo crude oil terminal, the existing five terminals are the Bonny terminal built by Shell Petroleum and now operated by Renaissance Africa Energy Limited, the Qua Iboe terminal built by Mobil Producing and operated by Seplat Energy, the Brass Oil River Terminal built by Nigerian Agip and now operated by Oando, the Forcados terminal built by Shell Petroleum now operated by Renaissance Africa Energy Limited, and the Escravos terminal which is built and operated by Chevron.

The commissioning of the first-ever indigenous Onshore Crude Oil Terminal in Nigeria, installed, owned, and operated by Green Energy International Limited, marks a historic milestone achieved by an indigenous company, which, was few months earlier, celebrated its first oil export from the Otakikpo field in Rivers State. This maiden crude export was completed in June 2025, after a successful crude injection.

The Chairman of Green Energy International Limited, Prof Anthony Adegbulugbe, has described the multi-million-dollar crude oil export terminal as an unprecedented feat achieved through dedicated teamwork, utmost commitment, and innovative ingenuity of the entire human resources value chain of the company.

Prof. Adegbulugbe highlighted that the Otakikpo crude oil export terminal facility is designed and built to accommodate four categories of upstream Investors. Those who will venture into crude transportation through trucking, barging, and pipelines of 20km and 40km, respectively.

“The Otakikpo terminal, which is the newest, is catering to four sets of E and P companies. The first set is those who have small reserves far away from oil export infrastructure pipeline, and they can’t afford to build a pipeline because of the small reserves”.

“This time around, they have a solution through a trucking option. That is, they can truck 1,000-1,500 barrels into our terminal. Getting to the terminal, we have a good road network. So, if you are around 50 kilometres or thereabouts, you can come to Otakikpo terminal”.

“Then, another set of companies has fields around creeks where they can’t do any trucking, but they can do barging. Again, we cater to those in that category. They can barge or even aggregate and come to where we call kilometre 6 because we already have a pipeline from our field to 6 kilometers offshore, and it is a bi-directional, which we are using right now for our export as we can turn it around”.

“You can bring your barge to kilometer 6, pump your oil onshore, and from onshore it goes directly into our terminal. So that again gives succour to those fields, and there are so many of them”.

“The third set of Investors are those who have fields 20 kilometers offshore. One of the mitigating factors for them for exporting is that they may not have enough capital to facilitate the required facility. Again, we have a 23-kilometre bi-directional pipeline offshore”.

“They can have a smaller vessel, produce and come to kilometer 23 and pump again onshore, and they can export”, Professor Adegbulugbe explained.

“The fourth set is the companies within 40 kilometres of us. Even if they have enough money for the required infrastructure, there is an issue of theft. They produce a hundred barrels and get paid sometimes about 80% with 20% loss, and that is impacting their bottom line. Again, we offer a solution”.

The Chairman, Green Energy International Limited stressed that the pipelines are designed to be in three phases as part of the strategies to ensure safety.

“All the pipelines coming to us are designed to be three-phase. Multipurpose solution. That is, you give us your oil, give us water, give us your gas. With gas in that pipeline, it is relatively safe from pipeline vandalism. We offer that solution. You are sure that if you bring your one hundred barrels to our terminal, you can get paid for 100 barrels. This is the kind of option we are bringing to the table”, Prof. Adegbulugbe concluded.

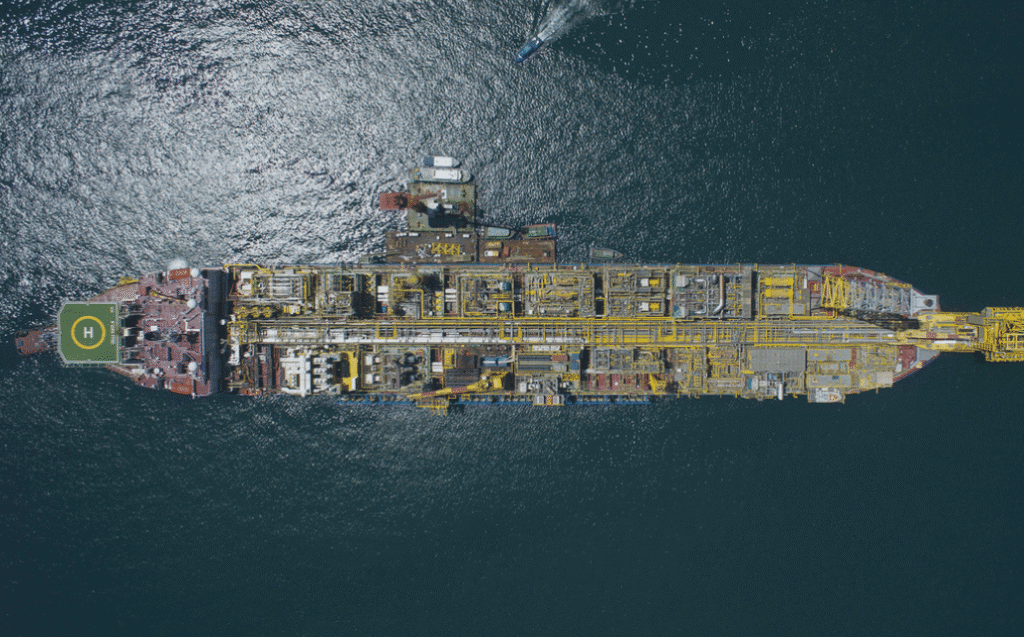

The Otakikpo crude terminal Project was commenced in the second quarter of 2023 and completed by the first quarter of 2025, behind schedule. The project’s first phase is estimated to cost 400 million Dollars, with a total phase development cost of over 1.3 billion Dollars. The Otakikpo terminal is designed to handle up to 250,000 barrels per day of crude oil injection, while the field currently produces at 10,000 barrels per day.

The Otakikpo terminal was developed in two years – six months ahead of schedule. The company broke ground on the construction of the facility in February 2023, with the development of storage facilities and the associated pipeline advancing in February 2024. Construction works continued to progress through May 2024, with associated infrastructure at the terminal – including offices and pump facilities – progressing in December 2024.

By March 2025, the facility began injecting crude, with GEIL’s production averaging 5,000 bpd. GEIL has since received regulatory approval from the government to boost production to 30,000 bpd under a revised field development plan. In June 2025, the facility received its first cargo via a vessel chartered by energy major Shell. The maiden cargo transported crude from the Otakikpo marginal field – located in Rivers State and operated by GEIL – to the terminal, kickstarting a new era of efficient crude distribution in Nigeria.

The terminal itself is a state-of-the-art facility with a storage capacity of 750,000 barrels. Plans are underway to increase storage capacity to three million barrels, dependent on market demands. The terminal is designed with an export capacity of 360,000 bpd, with crude transported via a 23-km, 20-inch pipeline connected to a single point mooring system in the Atlantic Ocean. At the site, tankers – such as Aframax chartered by Shell – can dock and load.

The terminal is expected to significantly reduce operating costs for marginal fields in OML 11, primarily through cost-effective transportation. Before the construction of the onshore terminal, GEIL relied on barges to transport crude. However, with the terminal, the company stands to reduce the reliance on costly offshore floating stations, reducing overall operational costs by 40%.