Frequent seismic monitoring is essential for the safe and permanent storage of CO2. Therefore, there is great joy among the consortium partners behind Project Greensand after it becomes clear that the seismic monitoring technology developed specifically for the project is proving successful.

The new technology ensures more frequent control of the Nini West field in the North Sea, while at the same time achieving less impact on the environment and climate. A wide range of consortium members are behind the newly developed technology, including the French company SpotLight:

“After the first CO2 storage, it was important for us to demonstrate the efficiency and flexibility of our monitoring solution. Among other things, we did this because we were able to quickly carry out the first monitoring of the reservoir and thereby obtain important information about where the stored CO2 is located in the reservoir. The operation was a great success, where we have collected high-quality data with safety and efficiency in mind. This enables Project Greensand to set new standards for CCS surveillance,” said Habib al Khatib, CEO of SpotLight.

On 8th March, H.K.H. Crown Prince Frederik signals to store the first CO2 in Denmark at the First Carbon Storage in Esbjerg. In just one month, the consortium partners have carried out a baseline measurement as well as two seismic monitoring measurements of the reservoir 1,800 meters below the seabed and can now conclude that the monitoring technology can safely and efficiently locate CO2 in the sandstone reservoir.

“During the first storage of CO2, it emerged that this method of spot measurement constitutes one of the most important innovative technologies in Project Greensand. We are therefore very pleased to see the technology become a reality with the monitoring and the successful results”, says Andreas Szabados, Asset Manager Denmark, Wintershall Dea.

The monitoring technology has been specially developed for Project Greensand, and it in itself represents a technological breakthrough. It works by examining sound movements at carefully selected points on the seabed above the reservoir. By comparing data from the selected points with previous calculations of the design of the reservoir, it becomes possible to say exactly where the CO2 is located in the reservoir and how it moves.

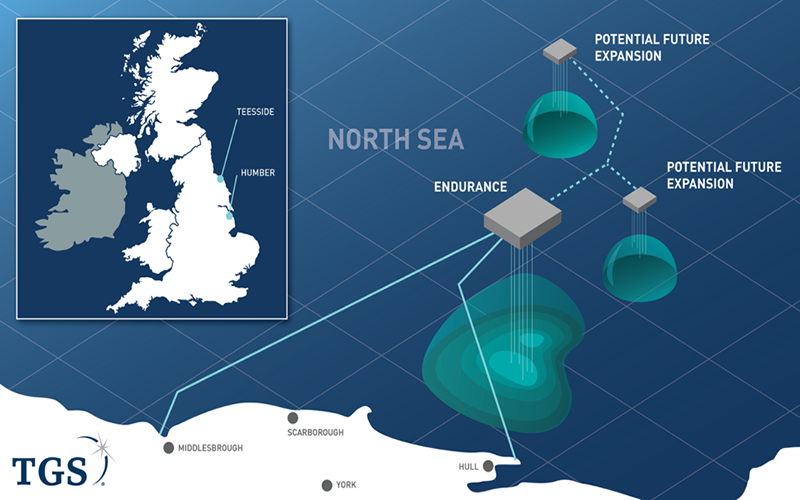

To acquire the seismic measurements, Project Greensand counts on the unique expertise of TGS, which, in addition to providing energy data and intelligence, specializes in equipment and operations for ocean bottom seismic measurements and modular solutions:: “Safety, flexibility and innovation are part of our DNA at TGS. We demonstrate this once again in Project Greensand. Together with our partners, we have shown that three seismic surveys can be performed only a few weeks apart during the North Sea winter season.. The operations were extremely efficient and were completed in just a few hours,” says Tone Holm-Trudeng, NES – Director of Offshore Subsurface Solutions at TGS.

Comparable offshore seismic measurements are traditionally made every few years, but now measurements can be made every few weeks and months, while the local marine environment is less affected.

“At the Danish Technological Institute, we are proud that we have contributed to the development and the first implementation of this effective and frequent monitoring solution. The environmental footprint is marginal compared to conventional solutions, and it has proven to resonate very well with people,” says Maj Frederiksen, Senior Project Manager from the Danish Technological Institute.

Esvagt is also very satisfied with the development of the new effective monitoring techniques.

“The operations have become more agile as we have carried them out offshore. Through our close cooperation, we managed to reduce the time required for the process between the baseline investigation and the follow-up monitoring. By leveraging our more than 40 years of operations in the North Sea, we are able to reduce the environmental footprint and significantly increase the efficiency of the operation,” says Nils Overgaard, Head of Special Projects at Esvagt.

Please wait....

Thank you for subscribing...