Greater recognition of technical challenges and a new, more collaborative approach to addressing them, is key to securing economic, environmental and security benefits linked to the growth in offshore wind, and keeping the UK at the vanguard of technology development, says Tony Quinn, Director of Technology Development at the Offshore Renewable Energy Catapult.

A number of key strategic UK goals are inextricably linked to the successful development and deployment of offshore wind, with Net Zero, economic growth, the Just Transition, and energy security key amongst them. Whilst recognition of this isn’t new, a failure to secure the much-heralded jobs boom from our world-leading offshore wind industry to date is widely acknowledged, with the reasons well understood: historic under-investment and a drive to deliver low carbon energy at the lowest possible cost have delivered a hugely successful industry in terms of deployment, but not yet local content or jobs at the levels many had hoped.

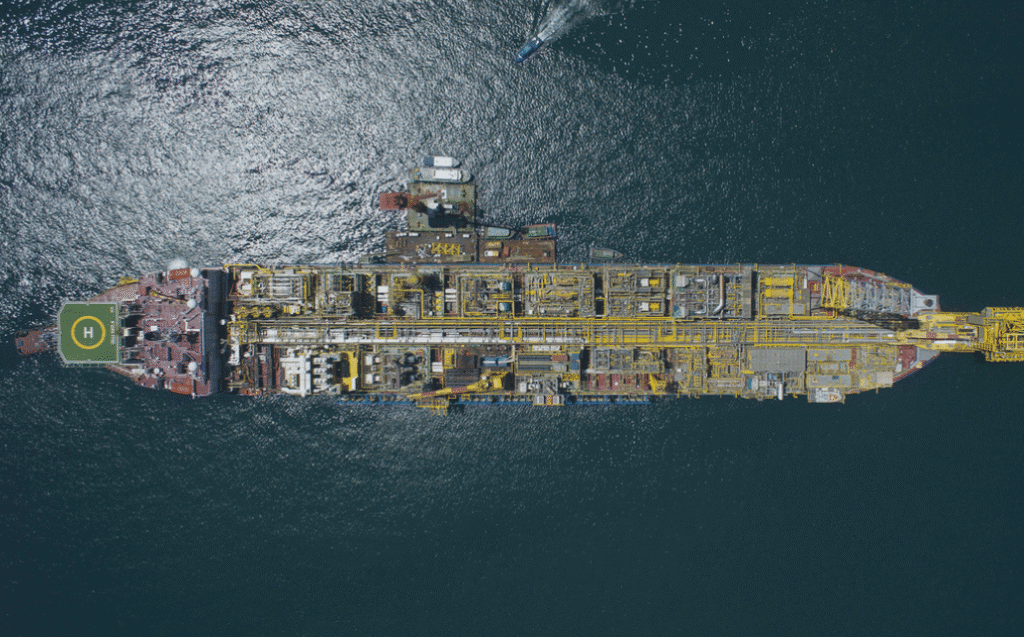

So, as we look to the continuing development of the industry, what lessons can we learn to avoid making the same mistakes, and ensure that we build a long-term and sustainable UK industry to replicate and replace that of North Sea oil and gas?

The Opportunity

There are several areas of technological development still required to fully exploit the potential that offshore wind presents. At the highest level they are:

- Continued development of the technology – power generation and distribution

- New applications of the technology – in particular moving from fixed bottom to floating wind.

- Improved asset stewardship – maximising reliability once installed through the use of digitisation, machine learning, and robotics.

- Industrialisation – power ‘stations’ are no longer ‘one off’ large centralised projects but now require thousands of units to be manufactured and installed using processes which are repeatable and assure quality.

Because there is far more of this industry ahead of us than behind us – these challenges present an opportunity for the UK to recapture lost ground in terms of local supply chain opportunities:

- The continued growth in turbine size which, despite slowing down in recent months, is expected to continue, driven in part by competition from new market entrants and the need to improve the economic viability of more challenging sites.

- Floating wind will enable deployment over larger areas further from shore with greater wind resource, but the application is not yet mature enough to realise the commercial opportunity. In order to capture its full economic potential we need to acknowledge and address the technological challenges it presents, and provide a clear route to commercialisation.

- Smarter operations and maintenance, with digital, robotic and artificial technologies, promise lower cost, greater reliability and lower risk operations.

- Production processes have evolved slowly, yet forecasts of offshore wind capacity out to 2050 represent a step change in both turbine size and turbine numbers. In order to realise the opportunity we need to move toward an environment of ‘design for manufacture’ in order to produce higher volumes of repeatable quality.

“Having identified offshore wind as the preferred form of low carbon power generation, we must identify the addressable opportunity, provide the right environment to tackle the remaining technical challenges, capitalise on our strengths, and make the smart, timely investments to address them.”

This is the key to capturing the real success that we all strive for; not just Net Zero, not just long-term energy security, but a sustainable industry, including UK manufacturing, generating UK economic growth, jobs, and exports.

The Problem

Learning by doing. Windfarms are currently being deployed on a project by project basis; as a consequence, lessons are learned in a very slow, linear, manner, often by a single stakeholder involved in the project (or at best by them and their close partners).

The absence of an industry led approach to meet the needs of the projects is resulting in a poor understanding, and indeed underestimation of, technology risk. In tandem, the project finance nature of windfarms is leading to a disproportionate allocation of that technology risk. Given the scale of the residual risk, the consequence is that no one fully benefits.

Successful industrialisation requires simultaneous maturing in three dimensions: the technology required to build at scale, the processes required to build at speed and with efficiency, and the capacity within the value chain to meet demand. To date we have focussed solely on the latter and, sadly, there is clear evidence that we’re struggling in all three dimensions.

A 2023 report from leading renewable energy insurers GCube (Vertical Limit: When is bigger not better in offshore wind’s race to scale?), draws on 10 years of claims data and other evidence to show how technology risk within the offshore wind industry has shifted significantly with the relentless drive for scale.

“An unprecedented number of mechanical breakdowns, component failures and serial defects are damaging the profits of manufacturers, placing pressure on the supply chain to keep up and leading to mounting project delays”, the report states.

In other words, achievement of scale for the promise it offers has outstripped industry’s ability to deliver technology assurance and reliability, leading to failures that are reflected in increased costs, introducing further stress into a supply chain already bearing the brunt of the understandable tight squeeze to drive down consumer bills.

These pressures have hit the OEMs hard, with all of the incumbent manufacturers reporting significant losses and warning that the pace of change and ever-downward margin trajectory are not sustainable. This has been exacerbated by inflationary and other market pressures leading to both project cancellations and the failure to secure any bids in the most recent round of Contracts for Difference auctions.

The Solution

At the heart of the solution is better understanding and management of risk and more equitable allocation of that risk. In order to achieve this it is essential that the UK develops its own competence in the technologies being deployed – not only to meet our own Net Zero, or security of supply, or local content ambitions – but to ensure we ‘keep the lights on’!

There are some relatively straightforward steps that can be taken to achieve this:

Creating the right environment for rapid development and validation of new technologies through investment in research infrastructure and programmes at scale – helping to de-risk the technology prior to deployment, providing a clear route to market and gaining early investor confidence.

There is evidence that this approach works. The deployment of the world’s largest turbines at Dogger Bank, GE’s Haliade X, was a huge achievement and testament to significant industrial collaboration. Bringing that technology to market in record time enabled the release of £9bn in funding for Dogger Bank (A&B), which is absolutely critical to meeting our Net Zero commitments. It was achieved in large part through a research and development programme of accelerated demonstration of both blades and powertrain at ORE Catapult’s facilities in Blyth, and generated significant experience and growth of technical competence in the assets being deployed.

Having the capacity to accelerate lifetime testing in controlled environments means shortening development timescales and driving early investor confidence; it is imperative that we build on and continually evolve that experience, and invest in the facilities to enable the development of next generation technology here in the UK. Failure to do so will result in late stage research and development of the next generation of turbines going overseas, and with it the associated learning, the Intellectual Property, large scale manufacturing and accompanying supply chain.

These test and demonstration facilities must be complemented by new ‘prototyping or industrialisation’ facilities. Such facilities will enable the trialling of new manufacturing processes and techniques outside of the main production line, creating the opportunity for robust validation before incorporation into that main production line.

A more equitable approach to the allocation of risk.

“Ultimately, all parts of the value chain -developers, operators, manufacturers, government, supply chain and taxpayers – have a stake in the success of offshore wind.”

Recent stresses in the supply chain, particularly amongst OEM’s, provide evidence that disproportionate levels of risk cannot be borne by a single entity in the value chain. The current model is therefore unsustainable.

Lessons should be learned from the hugely successful oil and gas industry which has long-adopted a different commercial model of risk allocation. The offshore wind sector, based on debt-finance and steered by the banks’ demand for a clear allocation of risk, has placed such responsibility solely onto the OEMs or EPC Contractors. In oil and gas, asset owners have taken far greater responsibility for addressing technical issues, bringing industry together to collectively invest in solving problems and then establishing new standards to reflect the collective learning.

A more equitable allocation of risk, with co-investment in the product development cycle, will foster a more collaborative and open approach to tackling the challenges, such that knowledge is shared and, as a consequence, every single future wind farm development will be more effective, efficient and resilient.

Iterative design improvements. A further benefit of this collaborative approach would be the improved use of data. Operational wind farm data is fundamental to helping iterative design improvement. At-scale test rigs gather vast quantities of further data on the performance of the prototype through accelerated life testing. Creating the right collaborative environment where the two data sets are combined would enable designers to go through the iterative improvement process in a far shorter timescale and once again accelerating progress through the maturity curve.

Such a way of working would raise knowledge and capability across the breadth of industry, at least in part replacing the current system that seeks to apportion blame and cost in an often litigious environment. It would accelerate the maturation of the industry not only for fixed-bottom but floating wind deployment too. With the right approach, and the use of independent organisations like ORE Catapult, it is possible to identify and address key industry challenges whilst creating the right environment to protect and foster the generation of IP, securing UK competitive advantage and providing heightened confidence to enable supply chain investment and growth.

It’s said that large ships take a long time to turn but, faced with a storm, turn they must.

“The offshore wind industry arguably presents the largest single growth opportunity in the UK today, addressing multiple political, societal and environmental objectives, but we will simply not realise those benefits without a reset now that addresses the fundamental challenges of technology risk, responsibility, and reward.”

That reset should look to a more collaborative approach, to the benefit of all stakeholders – from the largest developers to the end consumers.