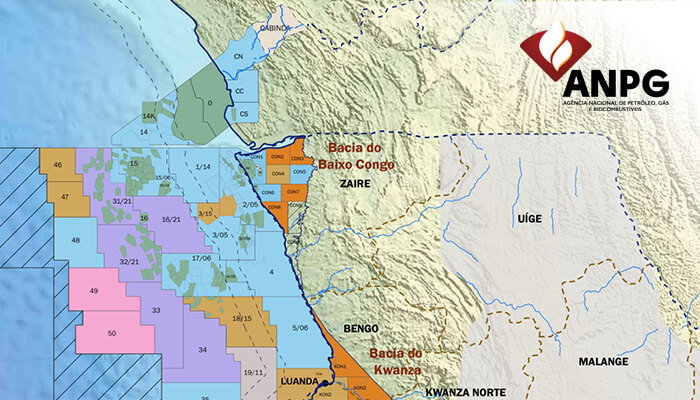

Trident Energy has been busy developing new ways of enhancing its production in Equatorial Guinea and the company is pleased to confirm the successful completion of its first deep offshore hot tapping operation, conducted on its CEIBA field which is located on the present-day continental slope.

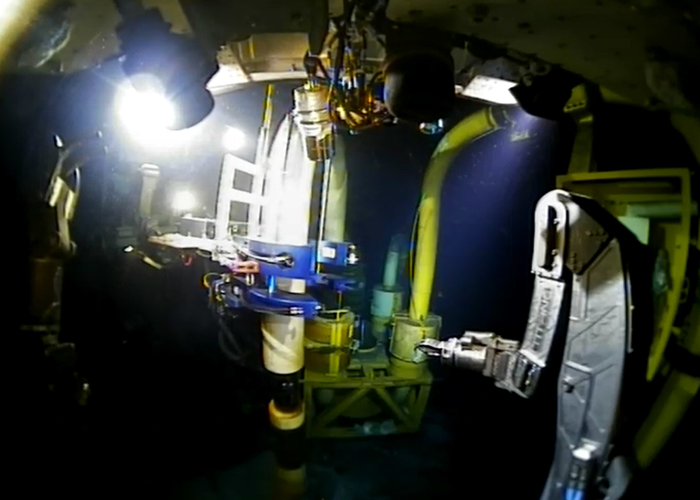

This innovative and complex method which was completed at a water depth of 780m, has allowed Trident Energy to create new gas injection points on two subsea production jumpers where there were none before.

The operation involved the London and Equatorial Guinea teams including experts from the onshore operations, production and offshore departments. Trident Energy was also supported by contractors including Trendsetter Engineering, IK Norway and Searov (a Deepocean Company).

With such a project comes a variety of health, safety and environmental risks which need to be carefully considered and managed especially as production remained in service whilst the operation took place. Utilising the expertise from the engineering and HSE teams and experienced contractors involved, the company investigated all possible risks and only proceeded with the process when it felt it was safe to do so.

Simon Lorelli, Subsea Operations Manager in London said: “I’m extremely happy with the success of this milestone project. It is testament to our onshore and offshore teams’ capabilities in challenging the industry.”

The Process

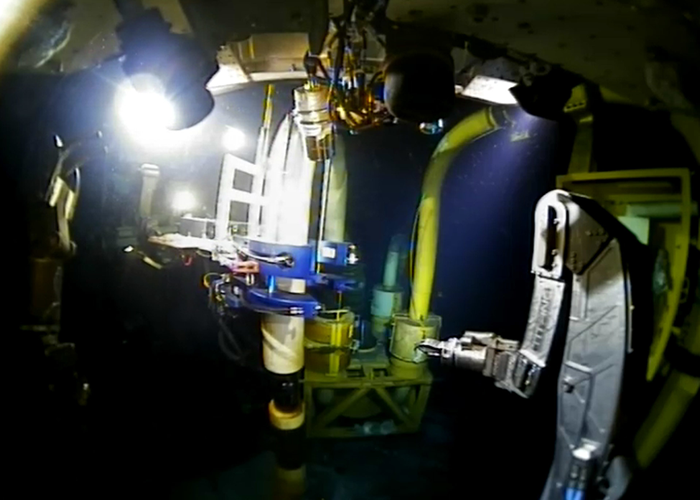

The process of hot tapping involved removing a targeted part of the thick coating that surrounds the pipe using a bespoke tool that Trident Energy alongside its chosen vendor, IK Norway, designed, engineered and tested. This tool is clamped around the pipe using a Remotely Operated Underwater Vehicle (ROV) to mill out the chosen part of the coating. Once this process is finished and the team is happy with the condition of the pipe, the ROV goes back to the surface so the installation of the hot tapping saddle can begin.

The ROV returns subsea with the hot tapping saddle (which is aligned and locked onto the pipe) and a drill unit. Before drilling commences the ROV performs checks and tests to ensure that the hot tapping saddle is sealed effectively onto the pipe. Once confirmed the drilling can start. Throughout this process the pressure on the clamp is carefully monitored and adjustments are made if necessary.

Once the drilling is completed, another series of sealing tests and checks are performed to confirm the success of the operation. The ROV then returns to the surface leaving the saddle clamp behind, ready for the next step in the project which is to attach a gas lift flexible flowline for the gas to be injected into the oil.

Jean-Michel Jacoulot, CEO, Trident Energy ML said: “I’m really proud of everyone involved in making this ground-breaking project at CEIBA a success. It’s a very complicated operation with a lot of risks involved but one we felt very capable of accomplishing. Projects such as these truly demonstrate the expertise and abilities of our experienced and passionate teams in bringing new life to mid-life oil and gas assets. Thank you to everyone involved.”

This is just one small part of Trident Energy’s strategy to further unlock the values of its oils and gas assets and ultimately enhance its production. Keep an eye out for further announcements!