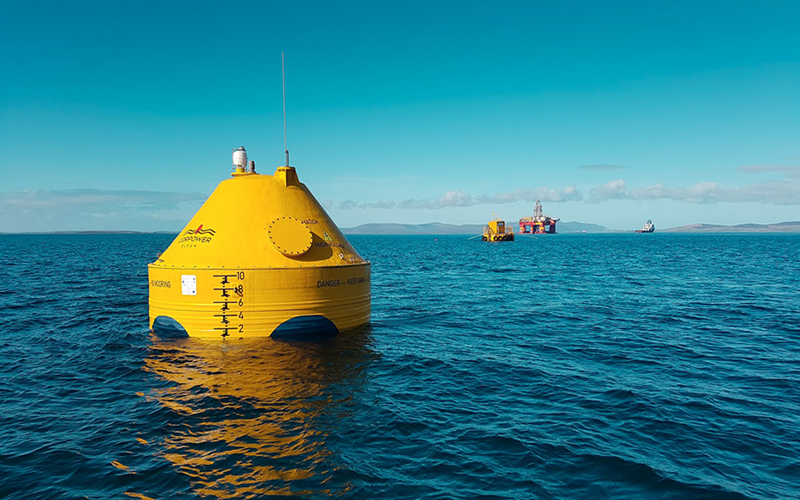

Bodycote, the world’s largest provider of heat treatments and specialist thermal processing services, is targeting the marine renewables sector after securing work with wave energy pioneer CorPower Ocean.

The UK-headquartered firm, which has built a long-term track record in automotive, aerospace, energy and broader industrial sectors, is now breaking into ocean energy after helping Swedish developer CorPower optimise key components in its Wave Energy Converters (WECs).

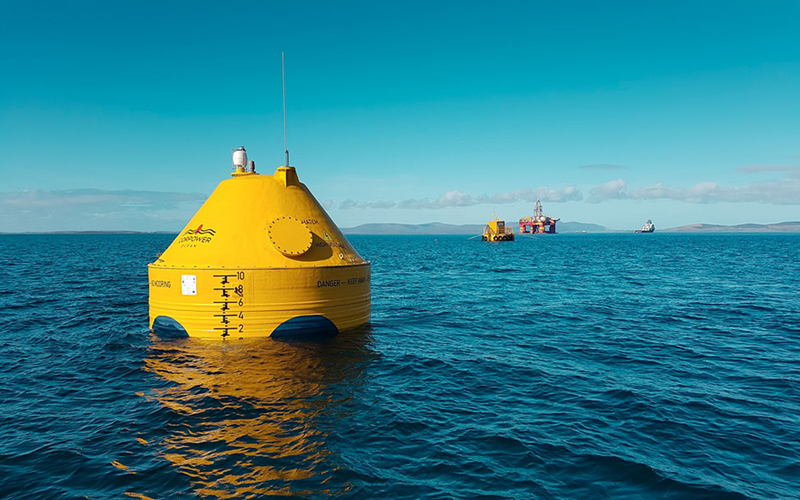

CorPower’s high-efficiency WECs, inspired by the pumping principles of the human heart, offer five times more energy per ton of device compared to previously known technologies. Incorporating a series of unique features to boost storm survivability and power capture, the WECs also benefit from thermochemical treatment to protect against the harshest marine conditions.

CorPower Ocean Senior Procurement and Quality Engineer Thomas Lindahl said: “After our initial collaboration we have now worked with Bodycote at a number of plant locations across Sweden to develop mechanical components for our WECs using Corr-I-Dur®. This thermochemical treatment simultaneously improves corrosion resistance and wear properties by generating an iron nitride-oxide compound layer. Durability and robustness are of paramount importance in the wave energy sector, and effective protection of devices in the hostile ocean environment has always presented a major challenge to our industry. Corr-I-Dur® has proved a particularly favourable solution being specifically designed for components subjected to a corrosive environment in combination with wear. From a commercial perspective, solid proof of the long-term resilience of our WECs makes them infinitely more valuable. We believe this collaboration will play a crucial role protecting our WECs during our next phase of testing in the Atlantic Ocean, and for the years to come.”

Bodycote President for Northern and Eastern Europe, Paul Clough, said: “We are pleased to be contributing to the marine renewable energy industry by making components last longer in extreme conditions. By using Corr-I-Dur®, CorPower was able to design mechanical components such as pistons, guides and linkages, that are suitable for the world’s harshest environments for metal. Our customers value Corr-I-Dur® for its ability to provide superior material properties such as wear and corrosion resistance, reducing maintenance costs and downtime for hard to access equipment. CorPower was looking to push the performance of their metal components through durability and corrosion resistance.”

CorPower Ocean is aiming to bring reliable and competitive wave energy technology to the world, unlocking one of the largest untapped sources of renewable energy – harnessing the natural power of the oceans to help us tackle climate change and achieve a sustainable low-carbon future.

The firm is now ramping up operations for its flagship HiWave-5 demonstration project in northern Portugal to propel its wave technology to a bankable product offering by 2024 – proving the survivability, performance and economics of a grid-connected array of WECs. The 16MEUR project includes investment to build a world-class wave energy hub in the Port of Viana do Castelo, involving R&D, Manufacturing and Servicing facilities for the lon With facilities in 23 countries, Bodycote is the world’s largest provider of heat treatments and specialist thermal processing services. Through classical heat treatment and specialist technologies, including Hot Isostatic Pressing (HIP), Bodycote improves the properties of metals and alloys, extending the life of vital components for a wide range of industries, including aerospace, defense, automotive, power generation, oil & gas, construction, medical and transportation. Customers in all of these industries have entrusted their products to Bodycote’s care for more than 50 years g-term development of supply and service capacity for commercial wave energy farms.